Sustainability is at the heart of everything we do. Our commitment to sustainability has contributed to our strong performance across the business and is fundamental to our success. We differentiate four sustainability pillars (Social, Industrial, Environmental, Corporate Governance & Financial) that are represented through our corporate social responsibility concept, environment, health & safety standards, sustainable forestry management, strong corporate governance, operational excellence practices, continuous R&D and innovations. All these are recognized contributions towards a greener, lighter and more sustainable future.

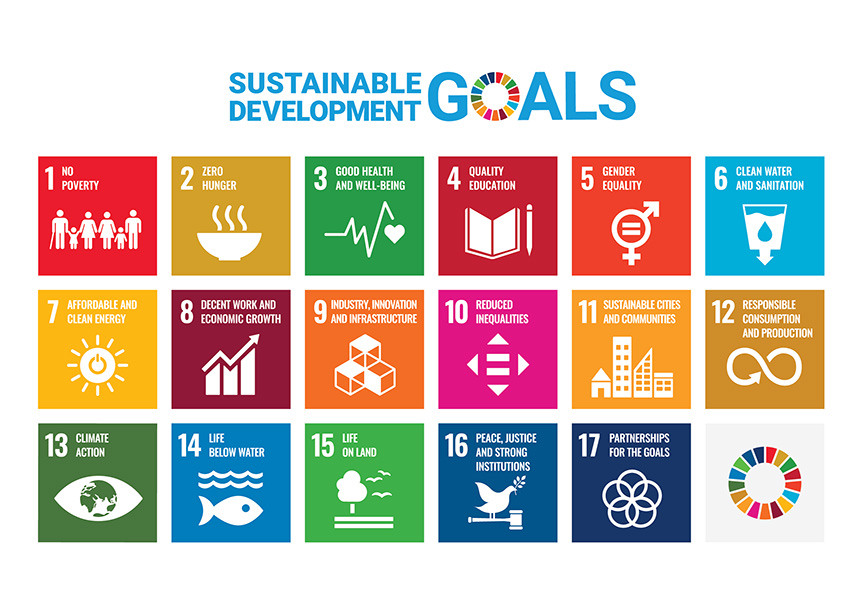

Our sustainability management approach is aligned with several of the United Nations Sustainable Development Goals (SDGs) and their associated targets. These goals came into effect on January 1st, 2016 as part of the United Nations 2030 Agenda for Sustainable Development. Our contributions to the goals that are most important to our sustainability agenda are described here.

Learn more

3ACM understands its responsibility towards forestry and nature and uses available soils according to their best use potential, allocating them only to sustainable

production practices and protects and guarantees conservation of the biodiversity.

In 2010, 3ACM was awarded the FSC® Certification as the first global producer and since then has maintained the FSC® Certification for our plantations in Ecuador and Papua New Guinea as our commitment towards sustainable forestry management, ensuring long-term plantation productive capacity and sustainable attention towards nature with FSC principles.

3A Composites Core Materials demonstrates its best practices through regular external certification and compliance with international golden standards. Quality Management System at all our sites demonstrates its compliance with ISO 9001:2015. The Environment Management practices at our Swiss site are certified with ISO 14001:2015 and Health and Safety Management practices - with ISO 45001:2018. We highlight our commitment to continuous improvement in relation to environmental, quality and H&S management with annual audits and re-certifications every three years.

Learn more

3ACM recognizes honest, transparent and fair business

conduct as fundamental to its operations. Our

commitments are included in the Global Code of

Conduct that applies throughout the company and is

binding to senior and middle management, as well

as to all employees, partners, customers and suppliers.

On top of being a responsible global employer and

partner, we recognize the commitment towards

financial performance and sustainable growth. We at

3ACM are fully aware of the company’s mission and

aspirational targets for sustainable development and

growth, acting towards increasing the value oering

and our customers’ experience. The company is

proud to show year-on-year sustainable financial results,

market positions, as well as being recognized

as a trustworthy and responsible long-term supplier,

business partner and employer.

Our approach of continuous

improvement, both in R&D and

sustainability areas, together with

established preventive risk-management

practices, secure our

position against short and longterm

risks

If you want to find out more about our sustainability activities and strategy or you just need to get any other information please do not hesitate to reach us.